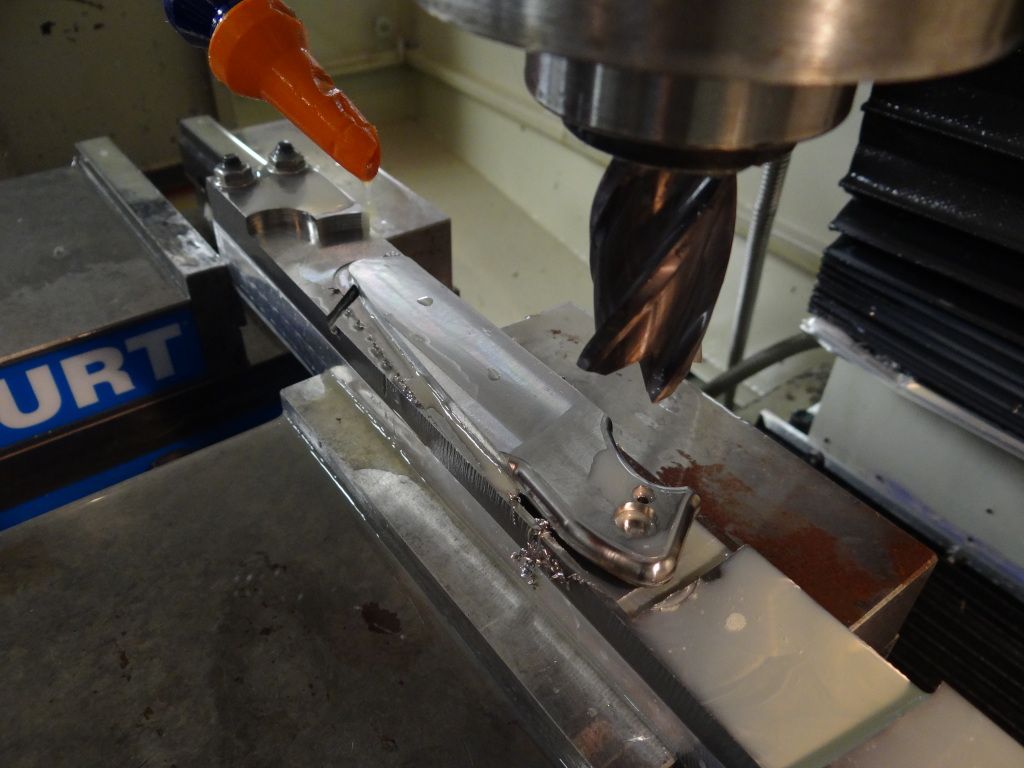

We continue with the sixth day of the Moon Framelock build. After angling the surface of the handle at 1.8 degrees, we used a roundover bit to round all the corners of the handle. This leaves the surface perfectly smooth with an even roundover throughout, and mates up with the bolster roundover perfectly to leave a smooth hand feel.

Next we've started to mill out the inlay area. Originally the idea was to mill a small and very intricate crop circle design, however it turns out to just not be feasible. The tool for routing out the small inlay area, a .018 carbide end mill, was just too delicate to function sucessfully with titanium, so the inlay design has been redesigned for a larger insert.

The inlay on this first knife will be flush fitting orange G10. By milling away the titanium in the handle and inlaying it with G10, not only is the knife a little more aesthetically appealing, but it also saves about a thrid of an ounce, not a lot, but enough to matter.

-Will